Microwave or Radio-Frequency ( RF ) PCB both belong to high frequency PCB , Radio-frequency (RF) and microwave (MW) circuits can be found in countless wireless products from handheld devices for medical and industrial applications to advanced communications systems for base stations, radar and global positioning.

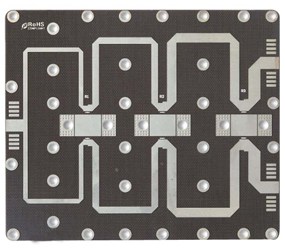

Microwave PCB

What is MICROWAVE & RF PCB ?

Electronic devices with MICROWAVE & RF is the developing tendency nowadays, especially in wireless network. Satellite communication growing rapidly, information products move towards high speed and high frequency. Thus developing new products always need to use high frequency substrate, satellite system, mobile telephone receiving base station and so on, these communication products must use MICROWAVE & RF PCB.

The features of MICROWAVE & RF PCB as following:

1. DK should be small and stable enough, usually the smaller the better, high DK may lead to signal transmission delay.

2. DF should be small, which mainly affect quality of signal transmission, the smaller DF could make smaller signal wastage accordingly.

3. The thermal expansivity should be the same with copper foil as much as possible, because the difference will lead to copper foil separated in the changes of cold and heat.

4. Water absorptivity must be low, high water absorptivity will affect DK and DF when in the wet environment.

5. Heat resisting property, chemistry resisting, impact endurance, peel off resisting must be good.

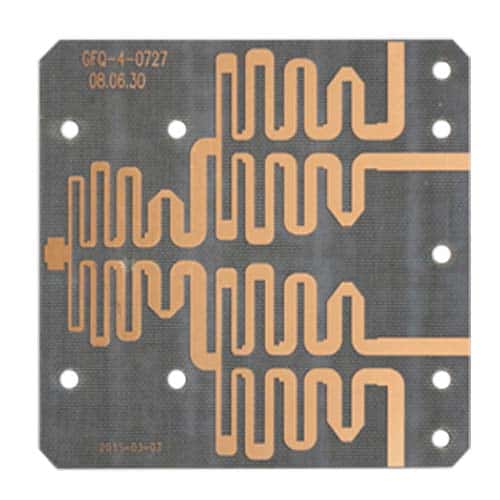

How to Select PCB materials for Microwave / RF PCB applications ?

Choosing a circuit material for a high-frequency printed-circuit board (PCB) is generally a tradeoff, often between price and performance. But PCB materials are also selected by two key factors: how well they meet the needs of an end-use application and what kind of effort is required to fabricate a desired circuit with a particular material.

RF PCB

These two factors may not mesh: one material may be well suited for a particular application but may pose challenges in terms of circuit fabrication, and vice versa. There is no foolproof, step-by-step procedure for selecting a PCB material. But by relying on some tangible guidelines designed to evaluate a material in terms of its suitability for circuit fabrication and for meeting the requirements of an application, the process of selecting a PCB for a particular application can be simplified. The approach will be demonstrated with some of the more popular high-frequency PCB materials, and where each stands in terms of fabrication qualities and suitability for end-applications.

Commercial high-frequency PCB materials can be categorized as one of seven generic material types, as shown in Table 1. High-performance FR-4 is included in Table 1 because it is often used in combination with other high-frequency materials for certain applications and requirements. However, in terms of electrical performance, FR-4 is not considered a true high-frequency circuit material.

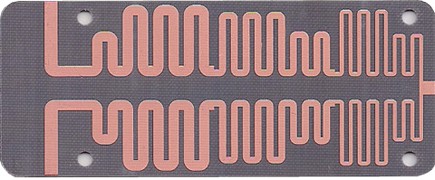

High Frequency PCB

JIeTeng Electronics provide Rogers , Isola, Arlon, Taconic , Teflon, Dupont to manufacture microwave and RF PCB Board. If you have any demand about high frequency , Please send mail to Sales@jtpcb.com.cn , We will give full manufacturing support to you .

|

Shenzhen JieTeng Precision Electronics Co., Ltd.

Contact Person: Sophia Wen

Mobile:13510797526

Q Q: 3342625352

Phone:0755-23500787

Fax: 0755-27099486

|

|

文章关键词:微波射频电路板 Microwave Radio-Frequency (RF) PCB