Manufacturing Multilayer PCBs (Up to 64 Layers)

The demand for multilayer PCBs has been on the rise. The drive for electronics to be smaller, faster, and more powerful has made the multilayer PCB much more popular. The ability to create multilayer boards opens up a world of possibilities allowing the engineer to create more densely populated circuit boards which allows miniaturization. This is a huge benefit that double sided boards are not able to offer.

Multilayer PCBs are only a little different that the Double Sided PCBs.

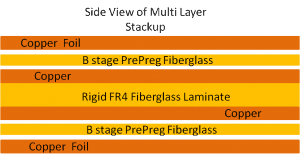

Multi Layer PCB Stackup As you can see in the image to the right, a four-layer board starts with a rigid core of FR4 and copper. The internal core is processed for traces on those prior to the other fiberglass and copper being added, and the entire board is laminated together.

Multi-layer PCB

There is the B stage PrePreg, which is fiberglass that is still soft that will need to be heated in order to become rigid. It acts like a glue to keep the inner core adhered to the outer copper foil.

The copper foil added consists of very thin and loose sheets of copper. They are sandwiched together with the Prepreg and inner core, and placed in a PCB Lamination Press. Pressure and heat are applied to the material, which causes the Prepreg to “flow” and bind the layers together. Once it cools, the fiberglass is then hard and the entire board is very rigid.

After lamination of the board, the outer layers are processed for traces and drilling. We will discuss those steps in greater detail in later articles.

That gives the basics of the starting material for a Double Sided PCB and Multi Layer PCB. Is it what you expected or thought it would be?

For Multilayer PCB , We support FR4, Rogers , Aluminum , Flexible PCB Material . Welcome to send your design to sales@jtpcb.com.cn

文章关键词:高多层板 Multilayer PCB